As a kind of fire-retardant, heat-resistant and insulating material, high-temperature bushing is more and more widely used in some high-temperature industries. But we will encounter a lot of problems when we choose the high temperature casing. Below, Xiaobian has sorted out some matters needing attention for you, hoping to help you.

1、 The high temperature casing should be purchased by the manufacturer with quality guarantee, which is more reliable in performance. If the high temperature casing produced by the irregular manufacturer is selected, there may be safety risks. If some parameters in the casing are unqualified, the consequences may be infinite.

2、 The price ratio of high temperature casing must be determined by choosing high temperature casing, because the price of high temperature casing on the market will fall, but it cannot be said that the higher the price is, the higher the quality. Some manufacturers in order to seek private profits, deceive those ignorant consumers, to fill the second, price is not said, but also poor quality, so in this respect must be more than three goods, more analysis.

3、 When purchasing high temperature casing, pay attention to the qualification and reputation of the manufacturer. The company has a long time to start and has a strong brand influence. The people who have bought the products say well, then you can choose.

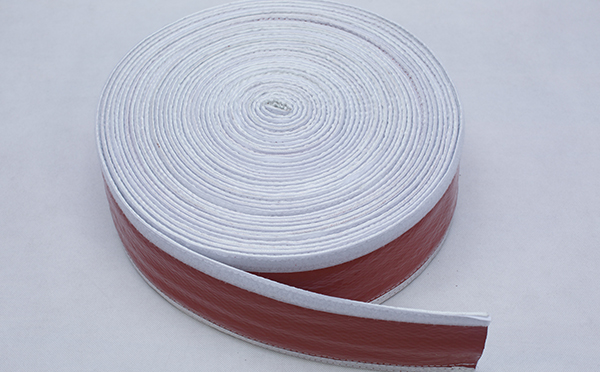

4、 After determining the manufacturer, first take a part of the sample, cut it out and see the glass fiber inside. The glass fiber in the high temperature casing is mostly white, and the very individual glass fiber will be milky white and light color. According to its color and outer silica gel, it is judged whether it is produced by the regular manufacturer. Many manufacturers in the production process are to save costs, Some other substances will be added into glass fiber, which will greatly affect the protective effect and service life of the casing.